Silica

With 540 million tonnes recoverable from a reserve of over 15 billion tonnes (in situ) in place, Sio’s resource provides a multi generational consistent and scalable SiO₂ resource.

About our Silica

Our silica is a unique natural resource and the primary invisible ingredient that keeps our society running. Sio Silica is known for its environmentally responsible extraction and processing methods, making it the greenest sand mine in the world.

Our innovative extraction method eliminates the need for truck traffic, surface mining, tunnelling, or dust generation—and no chemicals are used at any stage. All sites are fully reclaimed within a year, ensuring a light footprint and a responsible approach to land stewardship.

Combined with our state-of-the-art facility powered by renewable electricity, natural gas, and efficient processing systems, Sio Silica is making significant contributions to a low-carbon future.

Low iron silica

Few resource deposits in the world can produce a low iron, high purity silica.

< 100 ppm iron content

With simple wash and beneficiation, Sio can achieve silica below 100 ppm iron content.

Why low iron?

Low Iron Silica is the key requirement for manufacturing photovoltaic cells (solar panels) and smart glass, opening up a whole world of opportunities for touch screen display technology. Low iron increases transmissivity of light wavelengths for solar cover glass, specialty glass and touch screen dislays.

Unique uses

Low Iron silica is utilized in specialty glass for research industrial and aerospace.

Our resources

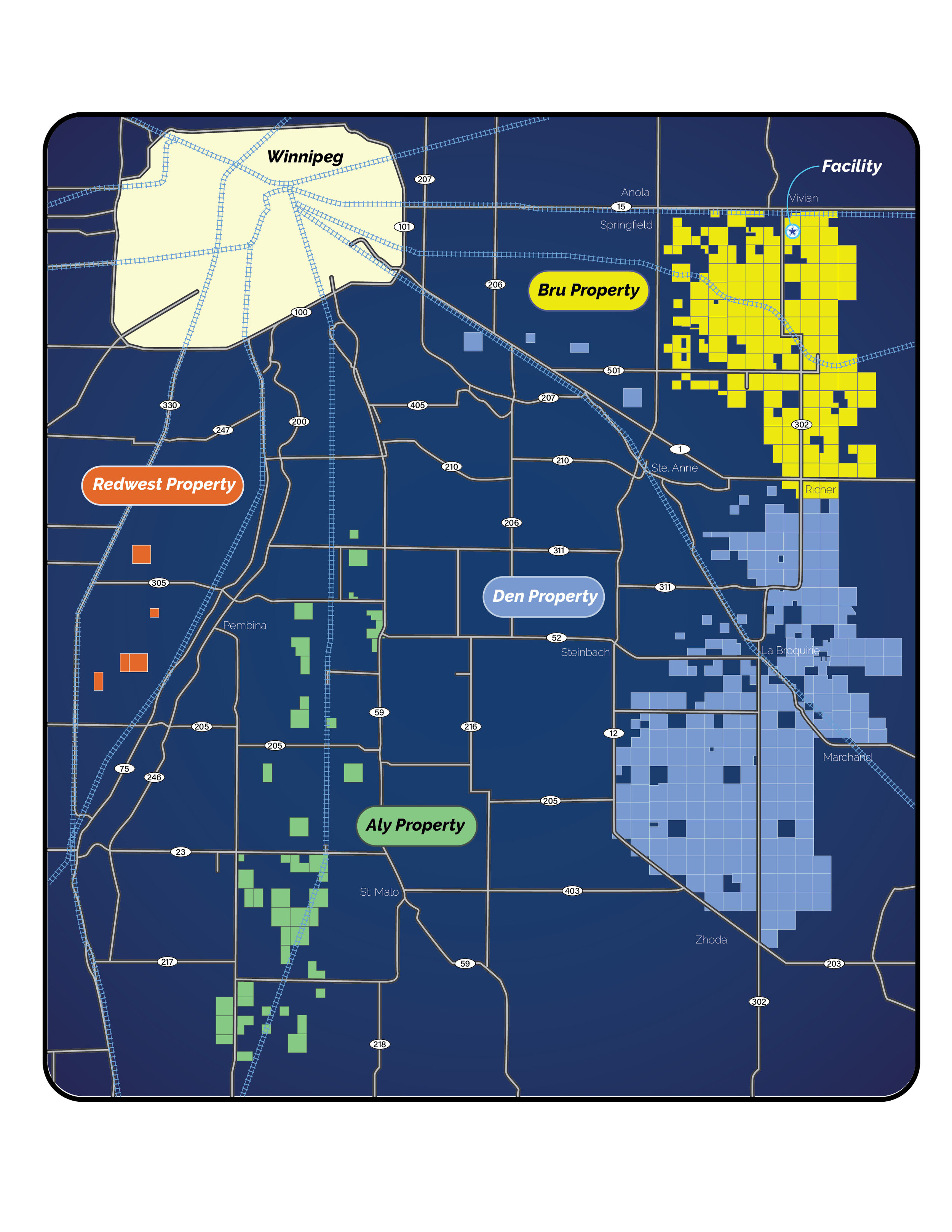

Sio Silica holds Canada’s largest known deposit of high purity quartz, with 459 mining claims secured across more than 100,000 hectares of land.

Our raw quartz consistently exceeds 99.85% purity even before processing, making it an essential and irreplaceable input for advanced high purity quartz applications. Over 98% of our quartz falls within the +40/-140 mesh size distribution, making it ideally suited for a wide range of high-tech and industrial uses. Strategically located near the inland port of Winnipeg, our facility offers direct access to all three Class 1 rail networks—CN, CP, and BNSF—enabling efficient and cost-effective transportation to North American and global markets.

Applications

Industrial silica has a significant role in how we live and is the primary invisible ingredient that keeps our society running.

Lithium Ion Batteries

Special Alloys

Aluminum Alloys

Silica Metals

Solar Cells

Electronics

Fiber Optics

Semiconductors

Optical Glass

Specialty Glass

Crucibles

Medical & Industrial Research

Aerospace

Porcelain

Cosmetics

Rubber

Coatings, Adhesive, Sealants

Micro-porous Battery

Synthetic Paper

Silica Desiccant

Foundation Sand

Investment Casting

Glass

Recreational

Water Filters

Energy

Our process

01.

Proprietary borehole extraction

Safe and proven method of extracting sand from below surface.

02.

Sand separation and return of water to aquifer

Reducing impact on local aquifer to almost net zero.

03.

Truckless wet sand transport to facility

Eliminating dust and truck traffic while transporting Silica.

04.

State of the art processing facility

Using renewable electricity and natural gas.

Get in touch

Message us using the form below to learn more about the process of high purity silica, or if you're looking for a new job opportunity.